This month the steam-boiler with flue gas condenser supplied by Frames at one of our valued customers passed the EBI (“Eerste Bijzondere Inspectie”). This is a mandatory inspection that checks whether the installation complies with the design and the applicable standards and regulations.

Recovered heat

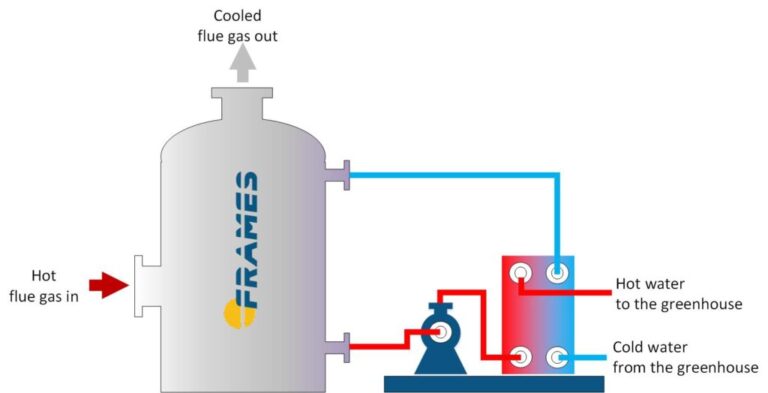

The Frames flue gas condenser (FGC) is integrated with a Vyncke biomass steam boiler. The FGC recovers -on average- an additional 2 MW of heat @ 65 degr.C from the flue gases. When combined with the steam from the boiler this heat can be used for the heating of greenhouses or for district heating.

Reduced Emissions

In addition to heat recovery, the FGC also reduces dust and ammonia (NH3) emissions. So-called PM2.5 emissions (particulate matter smaller than 2.5 µm.) is reduced by 20%.

Ammonia, which is a by-product of NOx reducing measures in the boiler, is lately coming under more scrutiny by regulators. The FGC washes the ammonia out of the flue gases ensuring it does not leave the chimney.

CO2 Capture ready (CCU)

The combination of the steam boiler and Frames FGC makes this boiler “CO2 Capture ready”. This means that without any modifications to the current installation, a Frames CO2 capture plant can be installed to capture clean, biogenic CO2 for use in greenhouses or industry.

Benefits

- Low-cost heat: 7,80 €/MWh considering OPEX and depreciation

- Reduced dust and ammonia emissions from the stack

- CO2 Capture ready (CCU)

- Integrated with the boiler and greenhouse heating water systems