Services for all your needs

Why to select Frames

Services for all your needs

Why choose Frames for maintenance?

Excellent product history backed by outstanding support services

Commissioning & Start-up

Ensuring safe and fast start-up of systems supplied by Frames and other suppliers.

You can be assured that all the systems and components are designed, installed, tested and perform according to operational requirements.

Operator Training

Operator training both on-site and in the classroom. It is our responsibility to train operators in such a way that they can operate the plant safely and in a reliable manner. Operators are trained by experienced Frames’ trainers representing multiple disciplines.

Training programs are customized to your specific needs.

Spares

We do not just replace old and worn out components with new ones. We can assist you with strategic spare parts consultancy to ensure your system’s uptime is maintained, operates reliably and meets desired availability.

- Spare parts supply, management and maintenance services

- Strategic spare parts stock consultancy

- Supply and/or hire of specialized operational/maintenance tools

Commissioning & Start-up

Ensuring safe and fast start-up of systems supplied by Frames and other suppliers.

You can be assured that all the systems and components are designed, installed, tested and perform according to operational requirements.

Operator Training

Operator training both on-site and in the classroom. It is our responsibility to train operators in such a way that they can operate the plant safely and in a reliable manner. Operators are trained by experienced Frames’ trainers representing multiple disciplines.

Training programs are customized to your specific needs.

Spares

We do not just replace old and worn out components with new ones. We can assist you with strategic spare parts consultancy to ensure your system’s uptime is maintained, operates reliably and meets desired availability.

- Spare parts supply, management and maintenance services

- Strategic spare parts stock consultancy

- Supply and/or hire of specialized operational/maintenance tools

Maintenance & Field Services

We support clients worldwide in the maintenance management of any system supplied by Frames or other suppliers:

- Reliability & Availability Management (RAM)

- Service Level Agreements (SLA)

Services Repair and Reconditioning

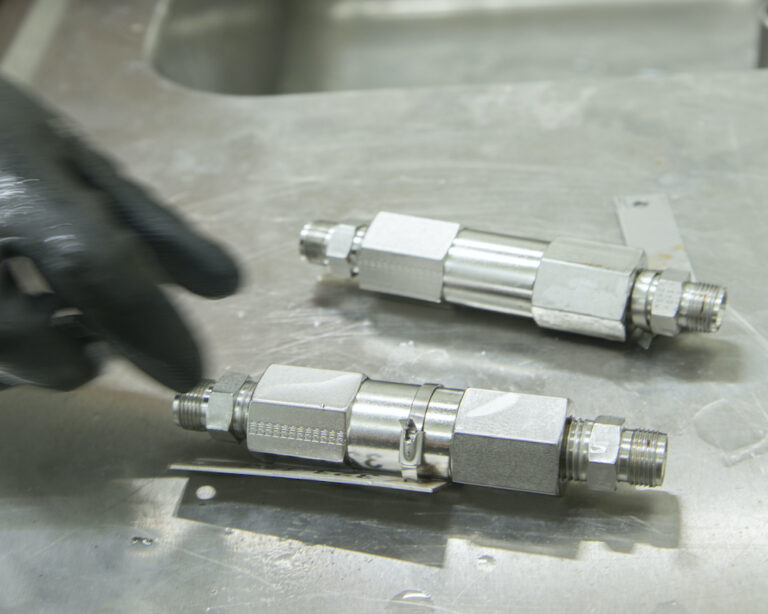

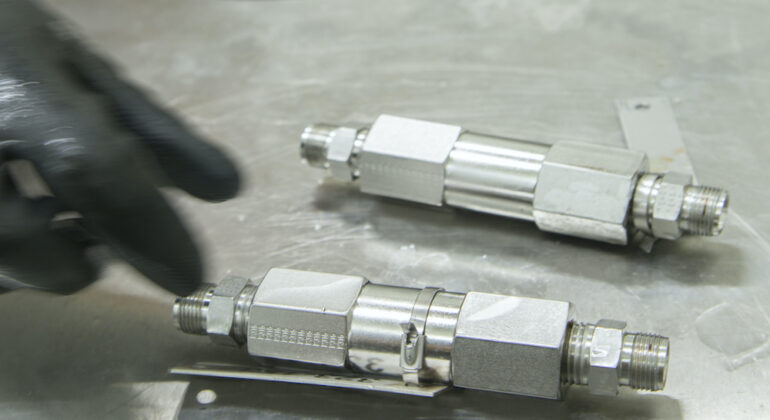

- Repair or overhaul of components

- Hot oil and water based fluid flushing

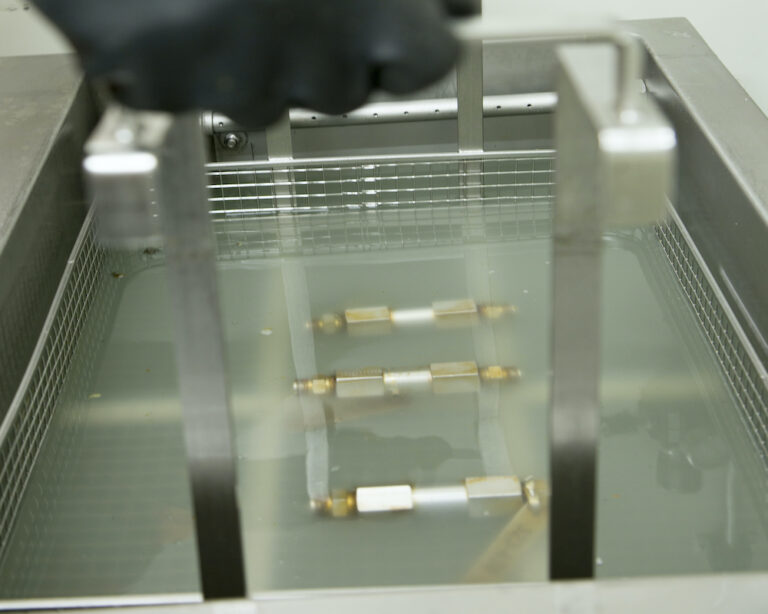

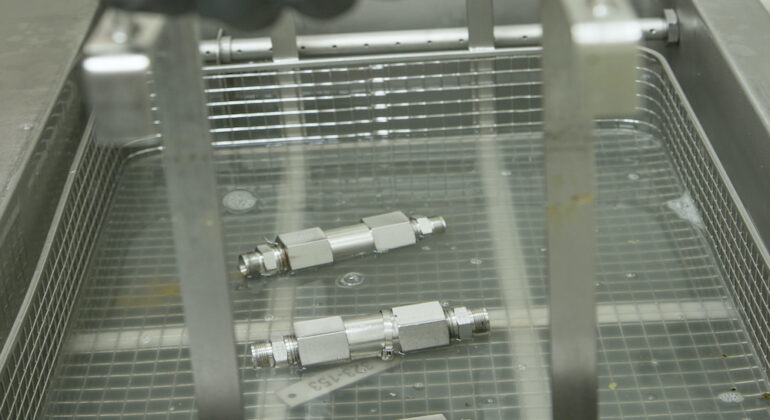

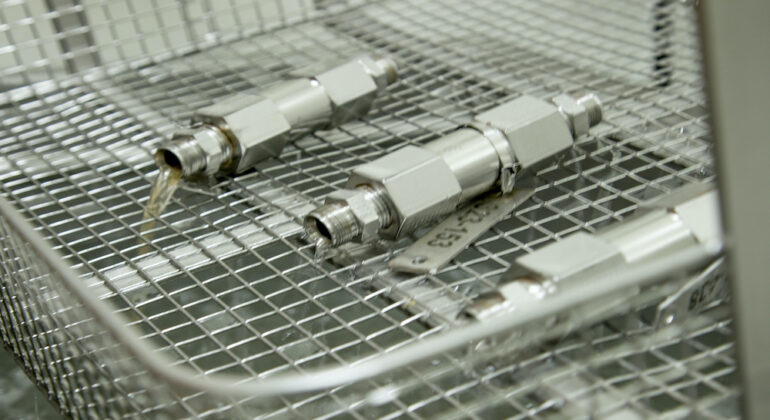

- Ultrasonic cleaning

- Function, pressure, and leak testing with a certificate

- Valve maintenance

- Hose testing

- Actuator repair available for most manufacturers

Maintenance & Field Services

We support clients worldwide in the maintenance management of any system supplied by Frames or other suppliers:

- Reliability & Availability Management (RAM)

- Service Level Agreements (SLA)

Services Repair and Reconditioning Shop

- Repair or overhaul of components

- Hot oil and water based fluid flushing

- Ultrasonic cleaning

- Function, pressure, and leak testing with a certificate

- Valve maintenance

- Hose testing

- Actuator repair available for most manufacturers

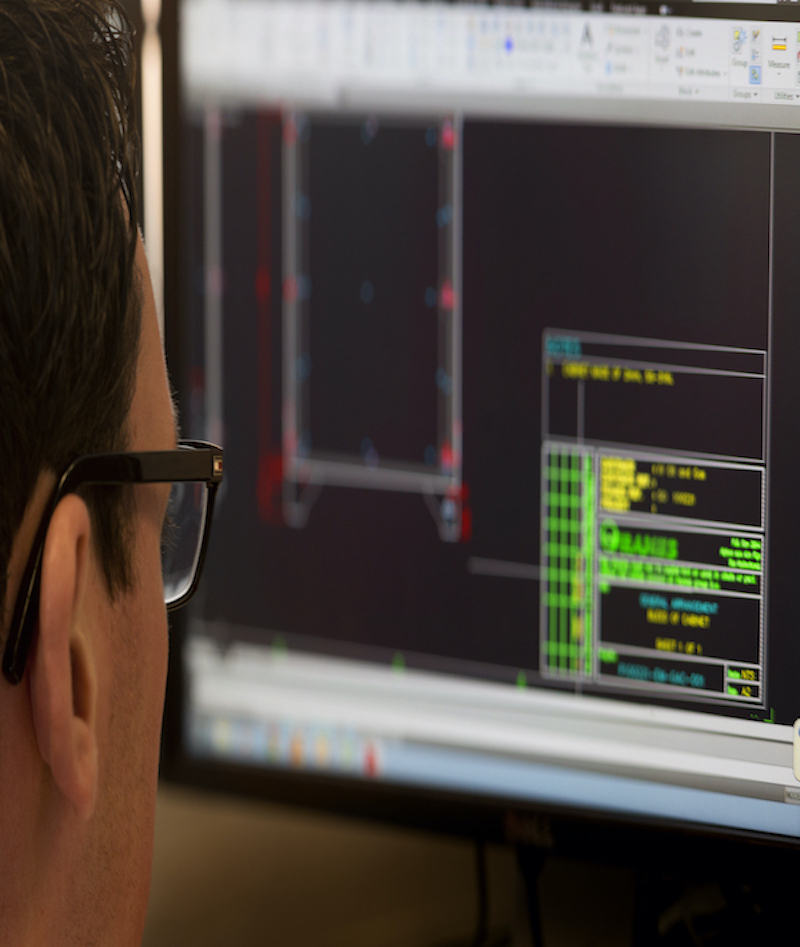

Engineering, Optimization and Modification Studies

Frames’ designs are based on optimizing CAPEX and OPEX by selecting the best development options for a client’s asset.

We support our clients with:

- Optimization and modification studies

- Conceptual and basic engineering design

- FEED studies

Frames is able to transform a client’s organizational strategies for day-to-day maintenance, taking into account cost, risk and performance. We use an asset management led approach that provides the following benefits:

- Predictable asset performance

- Investment planning

- Environmental and safety control

Providing services for our legacy products

Flow Control & Safeguarding

Wellsite Packages

Safety Instrumented Systems

Hydraulic Systems

Chemical Injection

Electrochlorination Systems

Oil & Water

Multiphase Separation

Electrostatic Coalescers

Produced Water Treatment

Gas

Gas and Liquid Dehydration

Gas and Liquid Sweetening and Sulfur Recovery

Dew Point Control

Hydrate Inhibition

Frames remains committed to providing service and support for our legacy projects. Our services will meet each individual client’s needs, upkeeping your asset’s performance. (* The Frames Renewable Energy Solutions projects will be provided by Green Gas & Liquids).

Contact form Services & Aftersales

Contacts

Eikenlaan 237

Alphen aan den Rijn

the Netherlands

Phone : +31 172 461 600

Marinus Verbaan (Mr.)

Caio Azevedo (Mr.)

Caio Azevedo (Mr.)

Commissioning and Start-up

Commissioning and Start-up

Operator Training

Maintenance & Field Services

Spare Parts

Frames provides support with:

Services Repair and Reconditioning Shop

We provide the following activities:

Services Repair and Reconditioning Shop

Engineering, optimization and modification studies

We support our Clients with:

Product development