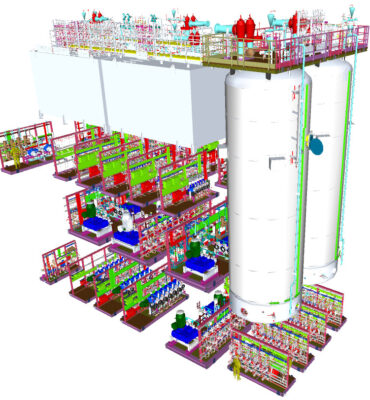

Frames successfully delivered the Chemical Injection Package scope for a FPSO.

The scope exists of:

- 26x Chemical Injection Packages

- 5x Multicompartment Storage Tanks

- 2x 145m3 Storage Vessels

with a total shipped weight of 320 tons.

The equipment will be shipped to China for further integration onto the FPSO!