December 10, 2021 | News

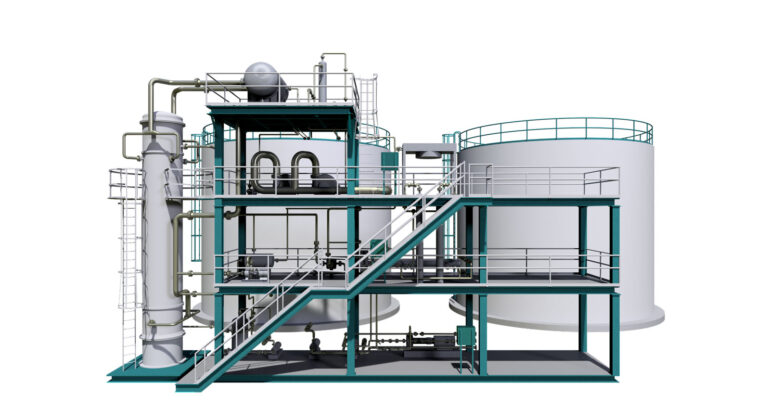

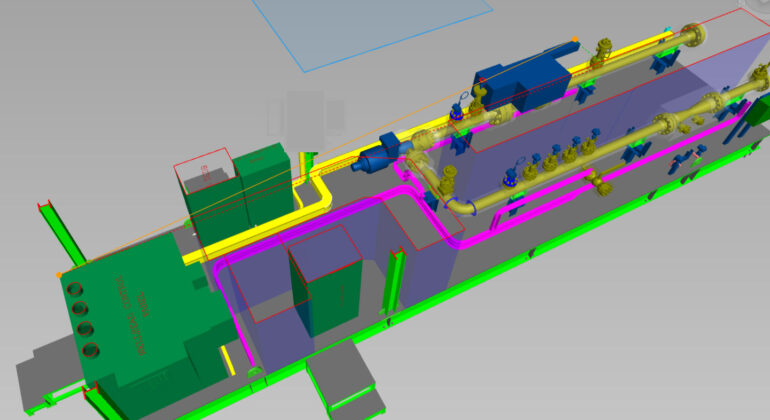

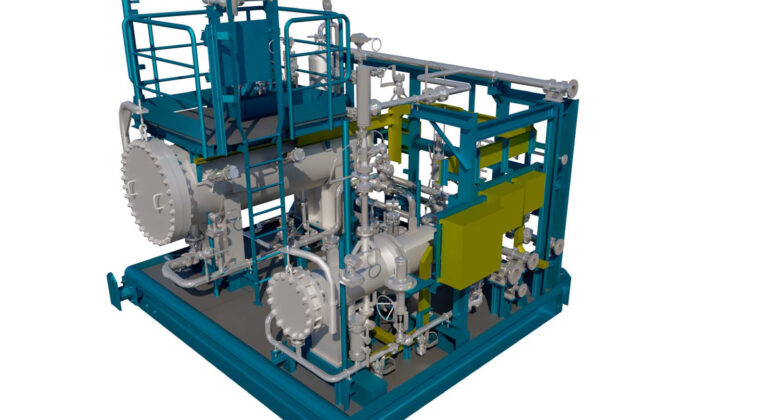

Today Plug Power completed an agreement to acquire Frames Group and welcomes 300 new employees to the Plug Power team.

Plug Power completes acquisition of Frames Group

Today Plug Power completed an agreement to acquire Frames Group and welcomes 300 new employees to the Plug Power team.